[Feed size]: No requirement

[Output size]: 2cm-10cm long and short materials

[Unit output]: 1-3 tons per hour

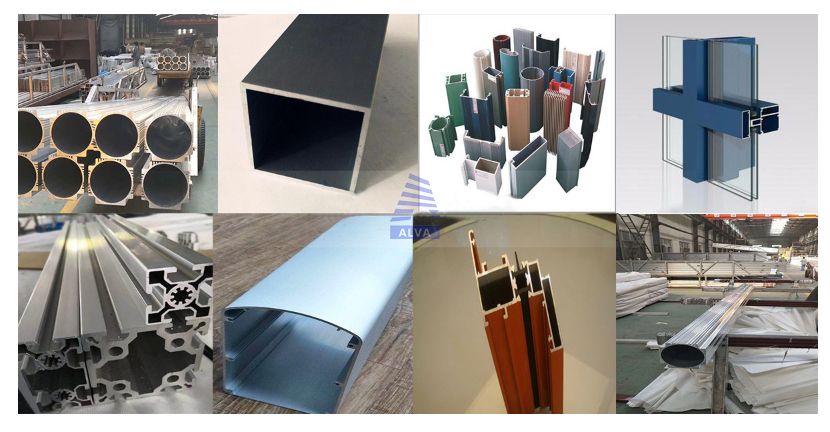

[Applicable materials]: scrap broken bridge aluminum, scrap aluminum door and window materials, scrap aluminum plates, aluminum alloy profiles, etc.

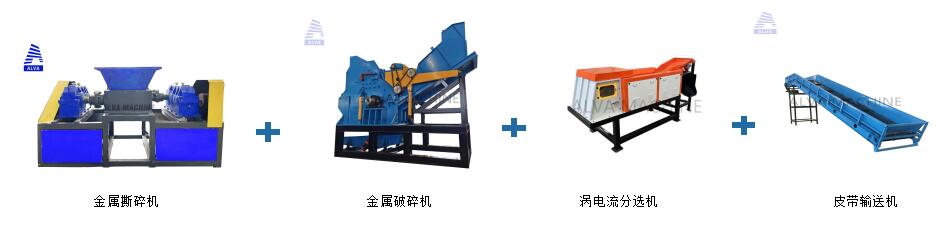

[Equipment composition]: Double-shaft shredder, bridge-breaking crusher, eddy current separator, belt conveyor

Production Line Composition

Equipment Solutions

The broken bridge aluminum crushing and sorting production line consists of a complete set of equipment production lines. The equipment specifically includes a broken bridge aluminum crusher, a magnetic separator, an eddy current separator, a belt conveyor, a bag dust collector and other series of equipment. It is a complete waste treatment equipment. Broken bridge aluminum crushing and sorting place

processing technology.

Waste broken bridge aluminum door and window materials are made of high-quality aluminum profiles, which have high recycling value. Through the broken bridge aluminum crushing and sorting process, the broken bridge aluminum, plastic, iron and other materials can be crushed and sorted to realize the recycling of different materials. Separation to maximize the recycling value of scrap broken bridge aluminum materials.

Equipment production line composition:

1. Metal shredder and bridge breaking aluminum crusher

a. The metal shredder adopts the principle of double-knife shaft rolling shearing of materials. It is driven by a motor and reducer. It has low speed and high torque to achieve the coarse crushing effect of materials.

b. The broken bridge aluminum crusher adopts the hammer crusher principle. The broken bridge aluminum is broken into particles by the high-speed rotation of the hammer head. The equipment body adopts a reinforced structure of extra thick steel plates and diagonal braces to ensure the crushing efficiency of the equipment. For overload requirements, the liner and hammer head are made of high-strength manganese steel wear-resistant materials, which increases the service life of the hammer head. The hammer head adopts a movable installation method and has strong crushing power. The bottom of the equipment adopts a unique large-hole grid structure, which greatly improves material discharge. efficiency.

Note: In actual production, the metal shredder and the broken bridge aluminum crusher can be selected from the two according to the size of the output material, or both coarse and fine crushing options can be used.

2.Magnetic separator

Magnetic separator, also called magnetic separator, is an essential part of the metal crushing and sorting production line. It is widely used in the crushing and recycling of scrap steel and scrap iron resources. Magnetic separators are used in metal crushers, scrap steel crushers, and scrap aluminum. Crusher is the most common iron removal machine.

3. Eddy current separator Eddy current separator, also called eddy current separator, metal separator, etc., can separate non-ferrous metals such as copper and aluminum from various metal crushing mixture materials, and can also be used in the environment Protection field, especially in the non-ferrous metal recycling industry. The eddy current separator is designed based on the principle that conductors generate induced current in the alternating magnetic field of the Normal University. During operation, a high alternating magnetic field is generated on the surface of the sorting magnetic roller. When conductive non-ferrous metals pass through the magnetic field, eddy currents will be induced in the non-ferrous metals. This eddy current itself will generate an eddy current in the opposite direction to the original magnetic field. Due to the magnetic field, non-ferrous metals (such as copper, aluminum, etc.) will leap forward along their transport direction due to the repulsive force of the magnetic field, achieving separation from other non-conductors or non-metallic substances to achieve the purpose of sorting.

4. Conveyor belts, loading machines and other accessories

Discharge particle size: The bridge breaking aluminum crusher is customized according to the discharge particle size.

Applicable materials: aluminum alloy tubes, building doors, windows, walls, broken bridge aluminum, indoor and outdoor decoration and aluminum profile materials for building structures.

Application areas: scrap aluminum profiles, broken bridge aluminum doors and windows, aluminum alloy scrap processing.

Features of bridge breaking aluminum crusher production line:

1. The equipment adopts densely distributed reinforced ribs to ensure the strength of the box. It has a wide feed opening and is suitable for raw materials with a large crushing volume. The crushing cavity is deep and has no dead space, which improves the feeding capacity and crushing effect.

2. Equipped with a hydraulic transmission system and built-in opening-top equipment, which can quickly perform inspection and maintenance of machine equipment and reduce shutdown time.

3. The bridge-breaking aluminum crusher production line can be freely configured, and dust collectors, vibrating screens, feeding and pressing devices, etc. can be freely added. At the same time, the equipment can also be equipped with magnetic separation equipment to separate non-ferrous metals and ferrous metals contained in the materials.