Cans are very commonly used in daily life, and of course they have become a very important part of waste recycling materials. Judging from the current recycling situation of waste cans, the recycling rate of scrap aluminum cans in my country is about 82%, which is the highest in the world for waste can recycling. Countries with higher recycling rates recycle at least 160,000 tons of waste cans every year, and the recycled waste cans are downgraded for use.

Application of recycling cans

The recycling and reuse of cans can not only save bauxite, but also save 92% of the energy consumed in aluminum smelting, making a huge contribution to protecting and beautifying the global environment. 1/4 of the recycled amount is used to make cans, and the rest is used as raw material for castings and die-casting parts to produce automobile parts, motor parts, etc., and part of it is used as a deoxidizer for steelmaking. Recycled aluminum ingots are made from cans, and then cans are made from recycled aluminum ingots, which can be recycled many times. No matter how many times the cans are reused, the quality will not be reduced. For the recycling of cans, one is to produce alloy aluminum ingots, and the other is to remelt to produce other aluminum ingots. This kind of aluminum ingots can be used in industries such as ferroalloys and steelmaking. This model seems to be more suitable for your current situation. When producing high-quality aluminum ingots by the remelting method, under strict operation conditions (whether using a reverberatory furnace or a crucible furnace), the highest direct aluminum recovery rate can only reach about 83%, which also includes refining from aluminum slag. Recycled inferior aluminum.

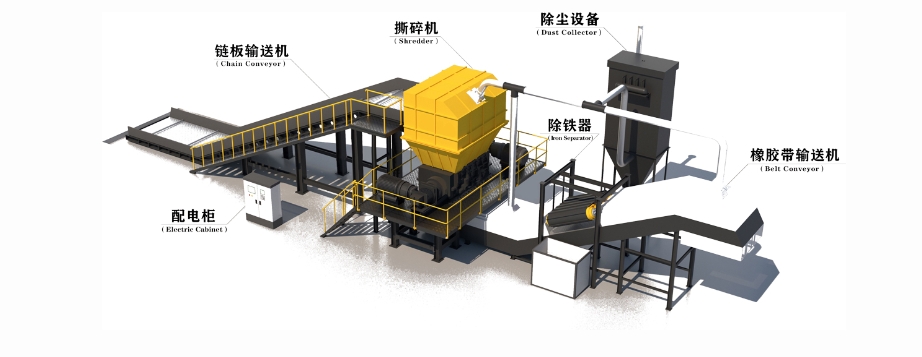

Waste can recycling process

The collected waste cans are first simply flattened and compressed, and at the same time sorted and rinsed. After being flattened and packaged, the can briquettes are shredded and crushed using a metal shredder and a can crusher, and then sorted. The machine accurately sorts and removes impurities from the materials to obtain clean scrap aluminum particles, which are then intensively “melted”. Under high temperatures, they will turn into liquid aluminum, and then into large aluminum ingots. The cans are ultimately melted down into recycled aluminum ingots.

Video demonstration of can crushing and recycling

1.Tear cans into pieces

2. Can flattening machine

3. Can shredding demonstration

4. Reference process of can crushing and processing production line