[Feed size]: Smaller than the diameter of the metal shredder feed opening

[Discharge size]: Scrap aluminum blocks of 3cm-10cml length

[Unit output]: 1-3 tons per hour

[Applicable materials]: scrap cars, car engine casings, scrap car wheels, scrap aluminum alloy doors and windows, etc.

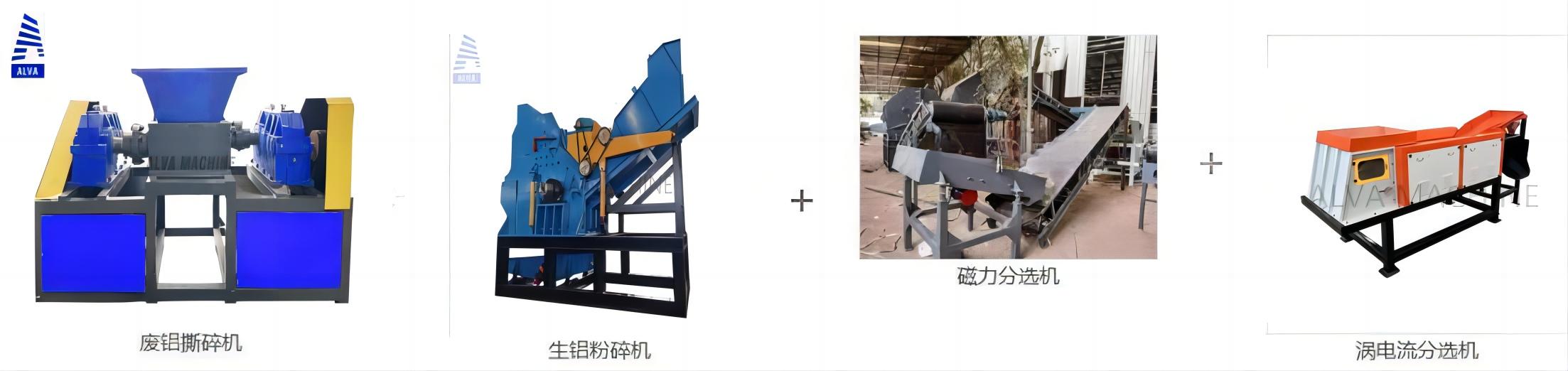

[Equipment composition]: scrap aluminum shredder, raw aluminum crusher, magnetic separator, eddy current separator

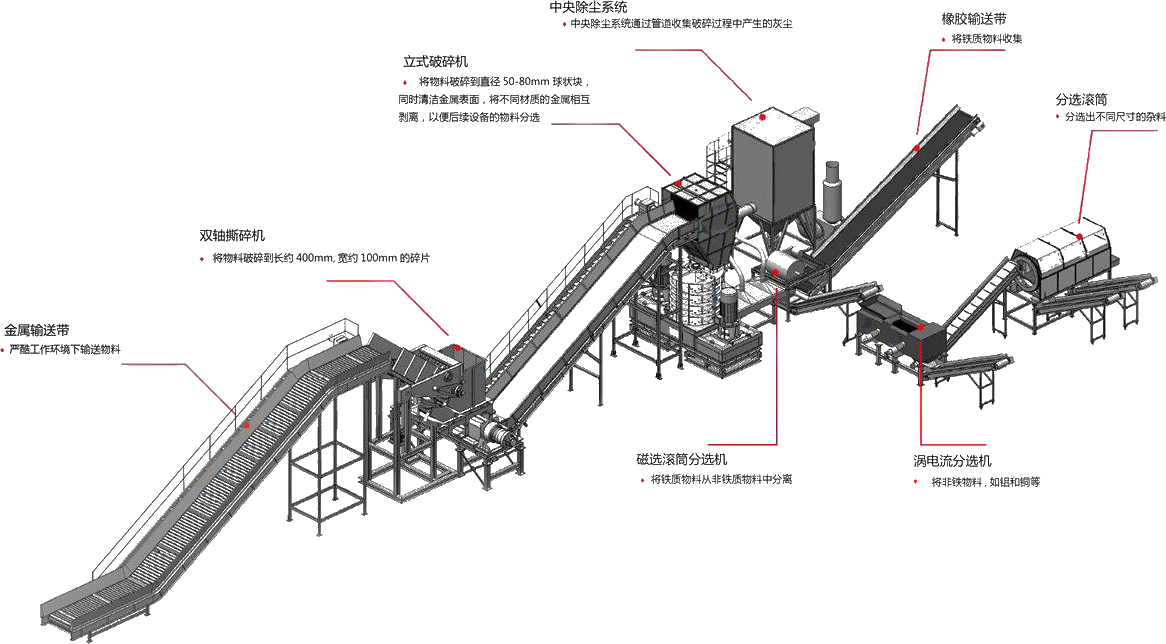

Production Line Composition

Equipment Solutions

The density of cast aluminum alloy is smaller than that of cast iron and cast steel, but its specific strength is higher. Therefore, using aluminum alloy castings under the same load conditions can reduce the weight of the structure. Therefore, aluminum alloy castings are widely used in the aviation industry and the manufacturing of power machinery and transportation machinery. Cast aluminum alloys are widely used in various molds, automobile engines, automobile wheels, equipment cooling accessories and other systems due to their high hardness, light weight and corrosion resistance.

In the recycling process of these cast aluminum alloys, due to their large size and high hardness, coarse crushing is required. The materials after coarse crushing are passed through a magnetic separator and multiple operations to complete the crushing, impurity removal and sorting of scrap aluminum materials.

Aluminum alloy wheel crushing renderings

Demonstration diagram of the actual operation process of aluminum alloy wheel crusher equipment

Note: In the process of crushing scrap aluminum profiles, a metal shredder is not required. It can be purchased according to the user’s production needs, or a scrap aluminum profile crusher can be purchased directly for processing. The combination of the two can increase the output per unit time.