[Feed size]: Smaller than the diameter of the metal shredder feed opening

[Discharge size]: 1cm-5cm diameter metal ball

[Unit output]: 1-3 tons per hour

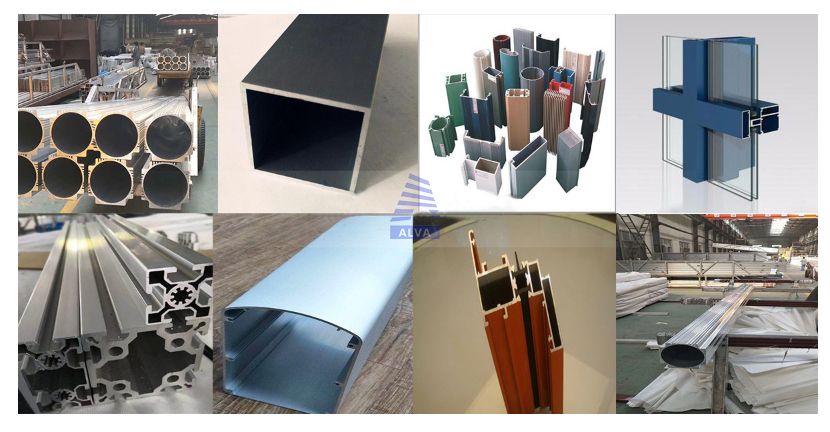

[Applicable materials]: scrap broken bridge aluminum, scrap aluminum profiles, aluminum alloys, scrap aluminum door materials, aluminum wire aluminum plates, etc.

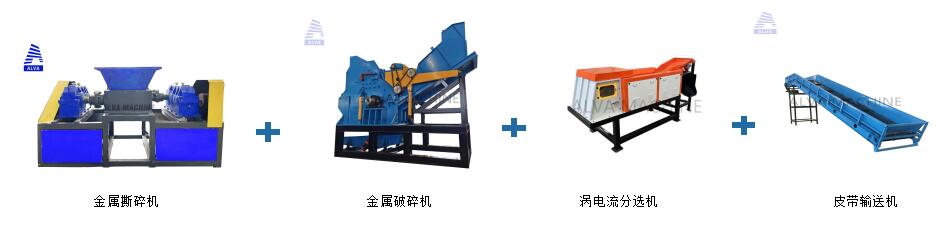

[Equipment Composition] Metal Shredder, Metal Crusher, Eddy Current Separator, Belt Conveyor

Production Line Composition

Scrap aluminum aluminum profiles are widely used in home decoration and industrial production. They are special materials used to process aluminum profiles for building doors, windows, curtain walls, indoor and outdoor decorations and building structures. After these materials are dismantled and discarded, they can be broken and sorted. Choose recycling to achieve efficient recycling of materials.

Equipment Solutions

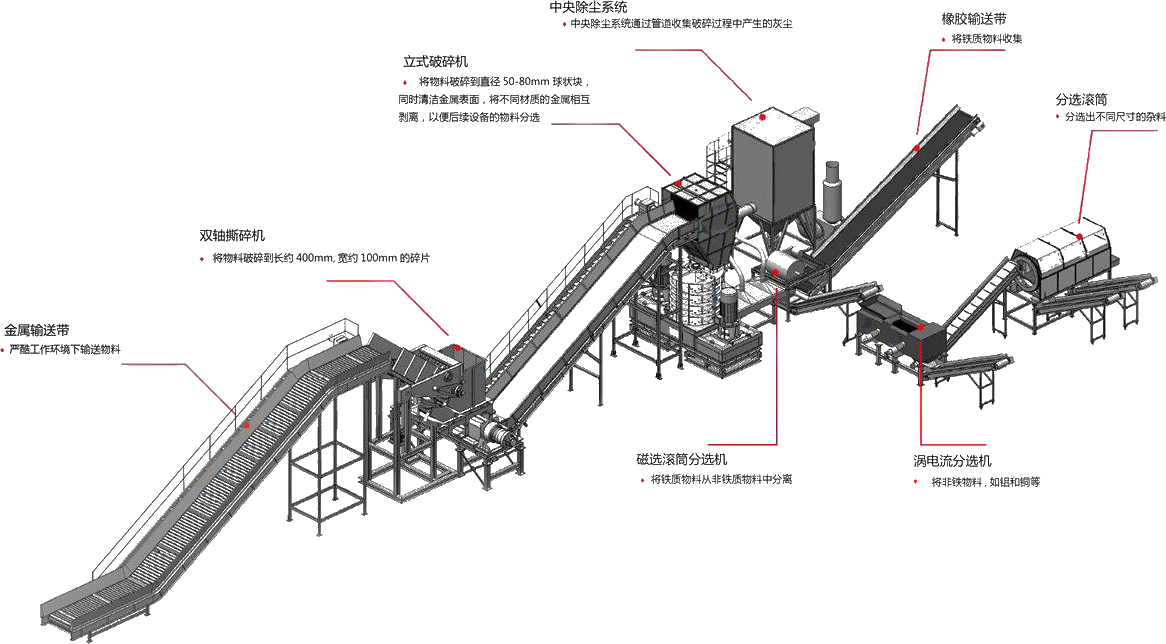

Scrap Aluminum Aluminum Profile Crushing and Recycling Production Process

Scrap aluminum aluminum profile materials can first be shredded to obtain broken aluminum profile rough materials. These rough materials can then be finely crushed using an aluminum profile crusher (metal crusher). The finely shredded aluminum profiles will become into aluminum metal balls of 1mm-3mm. During the material sorting process, the materials are sorted by magnetic separators, etc. to achieve complete separation of scrap iron, scrap aluminum and impurities, and finally obtain clean scrap aluminum particles. Secondary smelting recycling.

Note: In the process of crushing scrap aluminum profiles, a metal shredder is not required. It can be purchased according to the user’s production needs, or a scrap aluminum profile crusher can be purchased directly for processing. The combination of the two can increase the output per unit time.