[Feed size]: No requirement

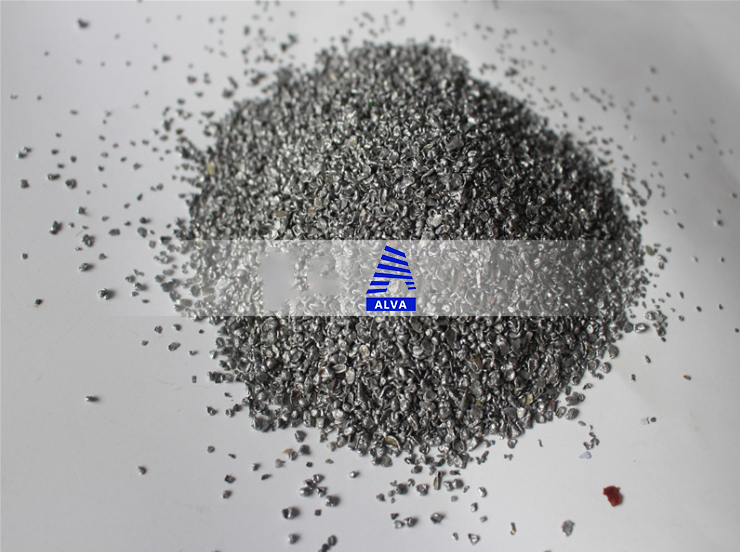

[Discharge size]: 1cm-3cm iron filings

[Unit output]: 1-3 tons per hour

[Applicable materials]: Iron filings, machine tool processing scraps, etc.

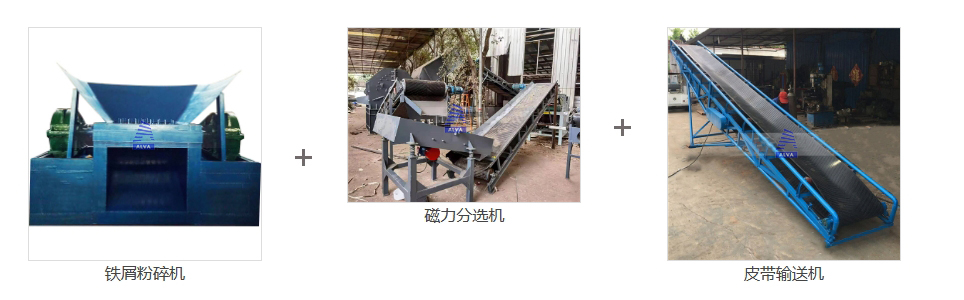

[Equipment composition]: Iron chip crusher, magnetic separator, belt conveyor, dust collector, etc.

Production Composition

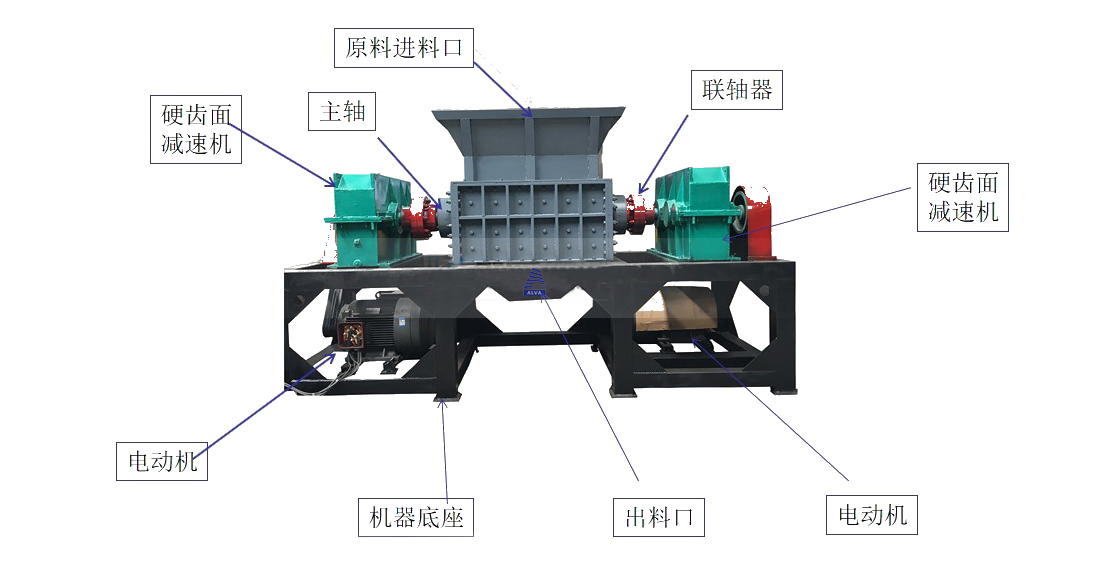

Iron chip crusher, also known as iron pin crusher and iron chip shredder. The iron scrap crusher equipment has a large feed opening, and the clumps of iron scrap materials can be easily cut and shredded. The production process is stable and the crushing effect is very significant. The iron chip crusher is mainly used for batch crushing of iron chips produced in various production workshops and machine tool processing, thereby greatly facilitating transportation, reducing transportation costs, and having a very high economic value. The equipment is suitable for crushing various steel scraps, copper scraps, aluminum scraps, iron scraps, scrap steel wires and other materials. It can shred them into very small metal particles. The crushed metal scraps can be directly used for steelmaking.

The iron chip crusher applies the principle of a double-shaft shredder. Driven by a high-speed and high-torque motor, it drives the speed of the reducers on both sides. The main shaft of the crusher is decelerated by the reducer, which greatly increases the torque of the main shaft, effectively crushing into crushing. Iron filings in the machine cavity are crushed into very small metal particles.

The iron chip crusher separates metals and non-metals through an air gyration sorting system. The entire system is equipped with a dust removal device to minimize the hazards of dust pollution generated during the production process.