[Feeding size]: The entire motor rotor can be fed as a whole

[Discharge size]: 1cm-3cm metal ball

[Unit output]: 1-2 tons per hour

[Applicable materials]: Various scrapped motors, pure copper rotors of motors

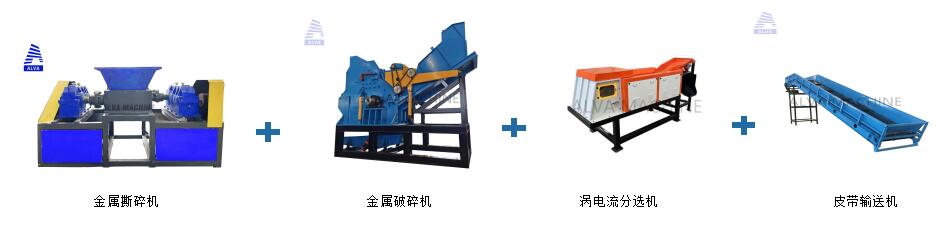

[Equipment composition]: Metal shredder, metal crusher, eddy current separator, belt conveyor

Production Line Composition

Iron chip crusher, also known as iron pin crusher and iron chip shredder. The iron scrap crusher equipment has a large feed opening, and the clumps of iron scrap materials can be easily cut and shredded. The production process is stable and the crushing effect is very significant. The iron chip crusher is mainly used to crush iron chips produced in various production workshops and machine tool processing, thereby greatly facilitating transportation, reducing transportation costs, and having a very high economic value. The equipment is suitable for crushing various steel scraps, copper scraps, aluminum scraps, iron scraps, scrap steel wires and other materials. It can shred them into very small metal particles. The crushed metal scraps can be directly used for steelmaking.

Motor Rotor Crusher Production Line Process

The working method of the motor rotor crusher is hammer crushing. The working principle is: the motor drives a high-speed rotating motion, strikes the scrap iron entering the crushing box and combines the rebound impact of the counterattack lining to finally complete the crushing of the copper material and filter it out. .

Prospects for crushing and sorting of motor rotors

The motor rotor is the core rotating component of the motor. The motor consists of two parts: a rotor and a stator. The motor rotor is divided into a motor rotor and a generator rotor. The current recycling price of used motor rotors on the market is about 50 yuan per ton, and the current price of copper is more than 30,000 yuan per ton. For every ton of broken electronic rotors, 0.25 tons of copper can be obtained, and the profit margin is huge. , and the development prospects are also good. The indispensable equipment is the waste motor rotor crusher. The motor rotor crusher equipment is an emerging waste recycling equipment. It is very popular among customers because of its powerful crushing force to completely separate the copper and iron in the motor rotor.

The motor rotor crusher production line adopts resource recovery equipment that is treated harmlessly by physical methods. The manually pre-sorted waste motor stator wire packets and other materials are transported to primary crushing and secondary crushing via a conveyor, and then sorted by strong magnetic rollers. The machine separates the silicon steel sheets and the copper mixture, and then the copper mixture is transported by the conveyor to the crusher for further crushing and refinement to obtain products with higher purity, and then transported by the conveyor to the air flow separator for sorting to obtain higher purity products. High copper particles and a small amount of debris.