[Feeding size]: The briquette can be fed in its entirety

[Discharge size]: 1cm-3cm metal ball

[Unit output]: 1-3 tons per hour

[Applicable materials]: Can briquettes, metal briquettes, iron sheets and other light and thin material briquettes.

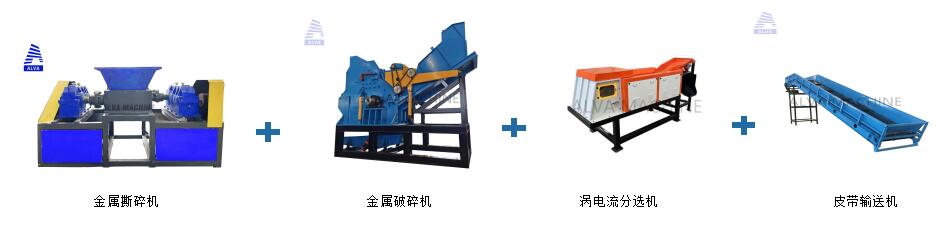

[Equipment composition]: Metal shredder, metal crusher, eddy current separator, belt conveyor

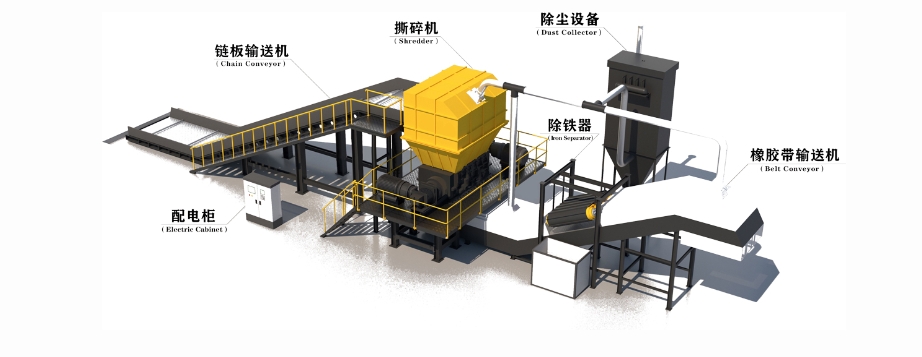

Equipment Solutions

Can briquettes and metal briquettes are common scrap metal materials purchased from various scrap collection stations. By compressing and packaging various similar materials, it is convenient for the transportation of materials. At the same time, because there may be different metal categories in the metal briquettes, There is a problem of fraud. Therefore, in order to improve the purity of scrap metal materials and reduce the energy consumption of metal refining, these can briquettes must be processed in different steps using a metal shredder and a metal briquette crusher.

Working principle of can metal briquetting shredding The metal briquetting shredder can mainly shred all kinds of materials that have been pressed into pieces by the metal briquetting machine. The materials are fed through the conveyor belt and enter the shredding chamber from the feeding port. The motor is driven by the gear box. The rotor is running, and the intermeshing rotors tear, squeeze and bite to shred the material into small pieces to meet the required size for secondary processing. The briquette shredder equipment is an auxiliary equipment that can be used to facilitate storage and transportation. The discharging size can be adjusted according to user requirements.

Advantages of can Briquetting Treatment Solution

The briquette shredder can shred aluminum briquettes, scrap bicycle briquettes, scrap steel bar briquettes, scrap car shell briquettes, iron sheet briquettes, packaging briquettes, etc. The equipment casing is automatically welded from 50mm thick steel plates, with high manganese steel lining plates inside and stirrups on the outside, making the whole machine strong and durable. Added stirrups make the whole machine strong and durable.

The metal briquetting shredder has a large processing range and high productivity. The most important thing is that it can remove debris and improve the performance and input-output ratio of steel products. If equipped with appropriate sorting equipment, non-ferrous metals mixed in scrap steel that are harmful to steelmaking can be sorted out, and very pure ferrous metal raw materials can be obtained. Therefore, the metal briquette shredding machine production line is currently the most ideal metal briquette shredding and crushing processing equipment in the world.

Equipment Composition of can Briquetting Production line

Cans and metal briquettes are processed by a metal shredder. The material obtained after coarse shredding is larger in size. If fine crushing is required, it can be purchased for further processing. In the material sorting, a magnetic separator is used to separate the iron and non-ferrous materials. Separate, and add an eddy current sorting machine to achieve the sorting of scrap aluminum materials, and finally obtain clean materials.