With the widespread application of lithium-ion batteries in new energy vehicles, electric tools, energy storage and other fields, the lithium-ion battery industry will usher in a period of rapid growth. In the next few years, China’s lithium batteries will usher in a large-scale retirement wave, which will lead to a large number of waste lithium batteries entering the market, and lithium battery recycling has become a hot topic of global concern. Due to the fact that waste lithium batteries are a very complex mixture containing many different components, especially precious metals such as lithium, nickel, cobalt, manganese, aluminum, etc., recycling waste lithium batteries can not only meet the needs of environmental protection, but also help to maximize economic value.

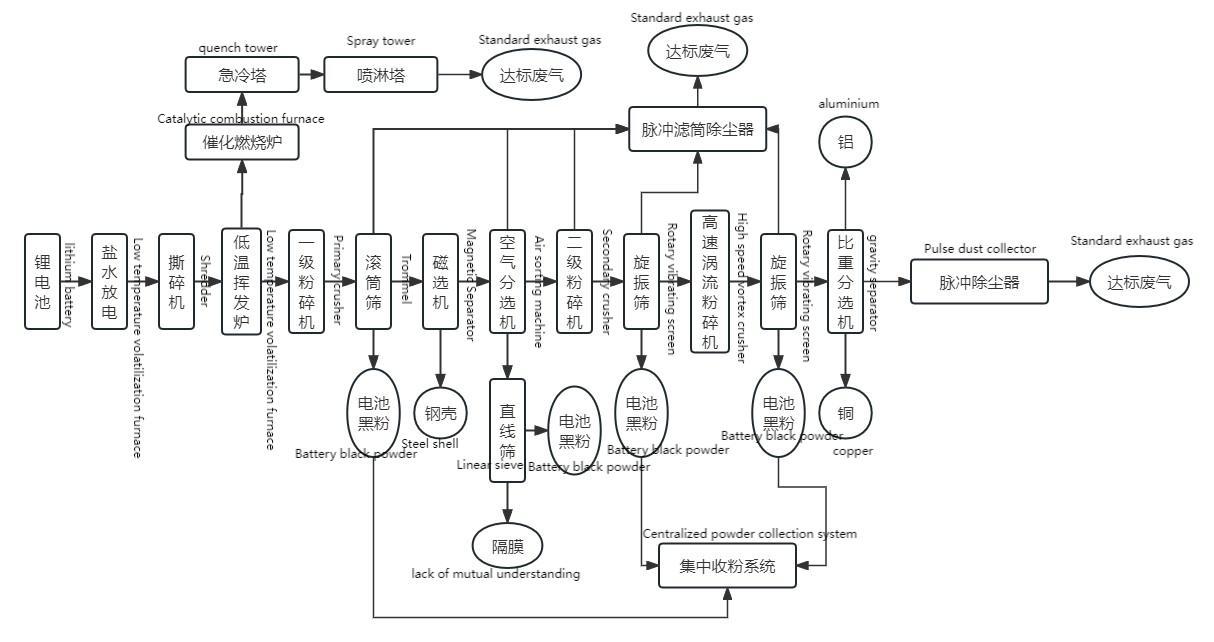

Working principle: Place the scrapped lithium battery in a container containing (5-10% concentration) sodium chloride saline solution and soak it for 48 hours to short-circuit the positive and negative electrodes of the battery, thereby completely discharging the battery and releasing excess energy from the scrapped battery.

Then, the waste lithium batteries are sent to the shredder, where they are crushed to about 25mm through shearing to facilitate the next processing step.

Subsequently, the pre crushed lithium battery is sent to a low-temperature volatilization furnace for external heating to dehydrate and dry the material for the next processing step. The organic waste gas generated during drying is treated by the flue gas treatment system and discharged in compliance with standards.

By driving the high-speed rotation of the hammer blade through the rotor, the material is hammered, cut, counterattacked, collided, and rubbed, causing it to enter one.

Step by step crushing and powder removal, the black powder removal rate in this stage is about 60%.

The material crushed by the primary crusher is sent to the fully sealed drum screen, and through flipping and rolling, the qualified material (black powder) is passed through.

Discharge through sieve holes. At this stage, the battery powder recovery rate is about 60%. Through magnetic attraction, the iron shell in the screened material of the fully sealed drum screen is separated.

Using aerodynamics to disperse materials, then separating heavy materials, and sending light materials (membranes) through a cyclone dust collector unloading hopper, heavy materials are directly sent from the heavy material discharge port to the sorting equipment, achieving the separation of light and heavy materials. At this stage, the diaphragm.The recovery rate is about 99%.

By driving the high-speed rotation of the hammer blade through the rotor, the material is hammered, cut, counterattacked, collided, and rubbed, causing it to enter one.

Step by step crushing and powder removal, the black powder removal rate in this stage is about 35%.

The material crushed by the secondary crusher is sent to the fully sealed drum screen, and through flipping and rolling, the qualified material (black powder) is passed through.

Discharge through sieve holes. At this stage, the battery powder recovery rate can reach about 95%.

Using a cutting disc to drive a fixed blade, it is tangent to the lining plate, and the material (mainly copper and aluminum) is crushed, kneaded, and ground to form a standard.

The granular structure of the grid allows for further refinement and powder removal, resulting in a black powder removal rate of approximately 99%.

The material crushed by the high-speed vortex crusher enters the rotary vibrating screen, and through vibration, the qualified material (battery powder) passes through the sieve holes.

Discharge. At this stage, the battery powder recovery rate can reach about 99%.

The comprehensive effect of reusing airflow and vibration friction on material production, where materials with high specific gravity (copper particles) settle to the bottom layer and pass through a sieve.

The vibration friction of the surface moves towards higher values, while materials with lower specific gravity (aluminum particles) are suspended on the surface of the material layer towards lower values under the action of airflow.

Flow around to achieve the purpose of separation by specific gravity. At this stage, the recovery rate of copper and aluminum is about 99%.