Due to the development of the economy, various types of cars have become indispensable means of transportation for every household, with the number constantly increasing. At the same time, this has exposed the shortcomings in the field of motor vehicle recycling and highlighted the huge market potential hidden in the dismantling equipment of scrapped cars.

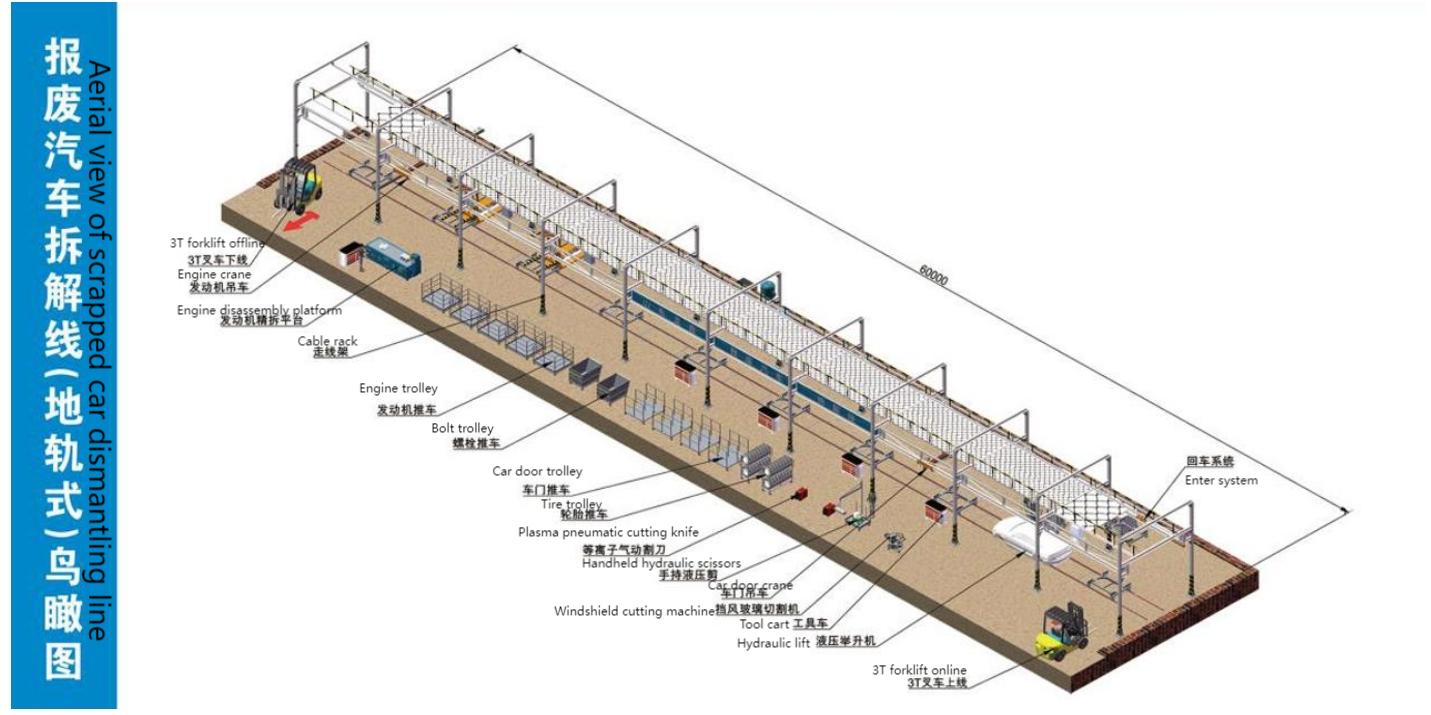

After dismantling, scrapped cars can be processed into products. If not handled properly, it can become garbage and even cause serious pollution. Turning scrapped cars into treasures requires fine classification. The production of assembly lines greatly improves the efficiency of car assembly. Under the new policy, the “five major assemblies” can only be handed over to qualified professional enterprises for reuse and treatment, and will not directly enter the market after dismantling, which can effectively prevent scrapped cars from entering the black market. The new regulations not only reflect the requirements for developing a circular economy, allowing scrapped motor vehicles to be remanufactured and reused, but are also expected to improve the economic benefits for consumers and recycling enterprises. Scrap car dismantling line and excellent scrap steel processing production line equipment, realizing modern green and environmentally friendly dismantling, crushing, classifying and processing automotive parts that can be used, testing and recycling, achieving refined dismantling and more reliable quality. Before the dismantling line for scrapped cars.

Jingkeqi believes that the components processed by the dismantling line can also be reused after technical treatment, achieving resource reuse and having excellent economic and environmental benefits.

There are two forms of pre-processing for large vehicles: sinking pit type and large tonnage lifting machine. Due to the large volume and weight of large vehicles, the pre-treatment station for large vehicles generally uses a sunken pit type oil discharge tank to remove waste oil.

Submerged pit type oil drain tank 20 ton lift

The general dimensions of a sunken pit type oil drain tank are: 9 meters long, 1 meter wide, and 1.5 meters deep. There are upper and lower steps left in the front and back, and a sliding rail is installed on the side. The oil pan is installed on the sliding rail and can move forward and backward.

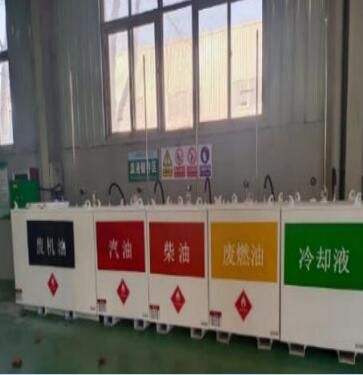

The pre-treatment equipment for fuel vehicles mainly consists of a lift, a fuel discharge drilling machine, a pumping machine, a waste oil collection device, a refrigerant recovery machine, and refrigerant recovery bottles.

1. Lift 2. Fuel Emission Drilling System 3. Oil Extraction and Drainage Device System

4. Waste oil collection device 5. refrigerant recovery machine 6. refrigerant recovery bottle

The pre-treatment station for new energy vehicles includes:

1. Power battery safety assessment charging and discharging equipment

2. Power battery disassembly device

3. Portal lift

4. Anti static insulation vacuum pumping unit

5. Anti static plastic interface refrigerant recycling machine

6. Special transfer box for power batteries

7. Safety protection and insulation protection equipment, tools, etc

1. Power battery safety assessment charging and discharging equipment 2. Power battery disassembly equipment 3. Portal lifting device

4. Anti static insulation vacuum pumping unit 5.anti-static plastic interface refrigerant recovery machine 6.dedicated transfer box for power batteries

7. Safety and insulation protection equipment and tools

(1) Safety protection and insulation (2) Insulation protective clothing (3) Eye washer (4) Insulation rod

protection equipment cabinet

a. Voltage endurance tester b. Insulation tester c. Temperature tester d. Leakage diagnosis instrument e. Digital clamp meter

f. High voltage testing rod g. Power battery power-off h. Power shut-off valve i. Insulation toolbox j.Medical first aid kit

equipment

Pre processing station dust removal system