Product brief introduction

Recycled broken bridge aluminum scraps, aluminum Windows and doors, waste aluminum and plastic and other materials how to deal with it? The treatment and recycling of broken bridge aluminum doors and Windows on the market is to separate aluminum and plastic, and the separated aluminum and plastic can be recycled and sold at a high price respectively. When separating aluminum and plastic, the waste aluminum crusher equipment should be used. When the waste aluminum crusher deals with broken bridge aluminum doors and Windows, it appears in the form of a whole production line.

Alva corporate purpose

Create value for customers, create benefits for partners, create future for employees, and create wealth for society Quality Policy

Excellent quality, perfect service, continuous improvement, meeting customer requirements

Chairman of Alva’s business philosophy:

To quote William Deming. Product quality is produced, not tested

Product quality is not shown in words, pictures, or videos, but is achieved step by step through continuous practice, innovation and reform. Every product of Alva is through technical research and development, production practice, and quality checks, and finally creates the most cost-effective products for our customers. Believe in China Alva, believe in your own choice. Alva never disappoints any client. thanks.

Product brief introduction

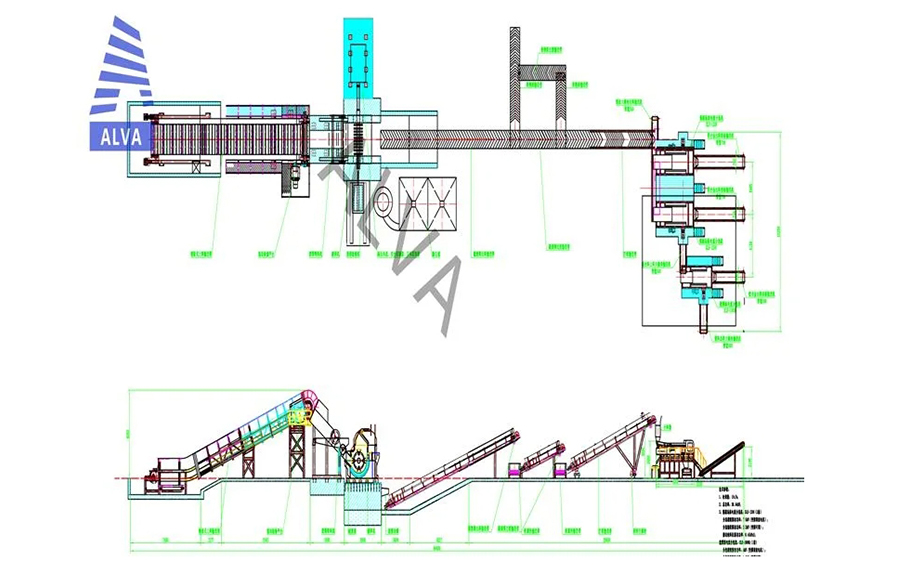

Recycled broken bridge aluminum scraps, aluminum Windows and doors, waste aluminum and plastic and other materials how to deal with it? The treatment and recycling of broken bridge aluminum doors and Windows on the market is to separate aluminum and plastic, and the separated aluminum and plastic can be recycled and sold at a high price respectively. When separating aluminum and plastic, the waste aluminum crusher equipment should be used. When the waste aluminum crusher deals with broken bridge aluminum doors and Windows, it appears in the form of a whole production line.

How to deal with the recycled old broken bridge aluminum doors and Windows? On the market, the waste aluminum crusher processing the broken bridge aluminum doors and Windows is a complete set of production line, including conveyor, main engine, discharge, sorting machine and so on can be used together. Its equipment includes two kinds of equipment, the broken bridge aluminum crusher and the eddy current sorting machine. The broken bridge aluminum crusher will break and process the broken bridge aluminum waste. The broken bridge aluminum inside the plastic heat insulation strip impact rub out, after the eddy current separator will be broken after the mixed materials for separation, aluminum and plastic completely separated, processed materials can be directly sold, increase the recycling value of aluminum and plastic.

The work of waste aluminum crusher is to effectively separate the aluminum material of broken bridge, and then carry out the separation processing through the eddy current separator. The eddy current separator is a kind of separation technology which makes use of the different electrical conductivity of the material. The sorting principle is to use the magnet rotor composed of magnet, and the rotor will produce alternating magnetic fields in the high speed rotation. When the metal with conductance passes through the magnetic field, it will induce eddy current in the metal. The eddy current itself will generate alternating magnetic field and the magnetic field generated by the rotation of the magnet rotor is contrary to the non-ferrous metal (copper, aluminum, zinc, tin) will jump out along the conveying direction due to repulsion; It can be separated from plastics and other nonmetallic materials to achieve the purpose of sorting. The eddy current sorter has the advantages of simple operation and high separation rate, and it has good sorting effect on a variety of non ferrous metals.

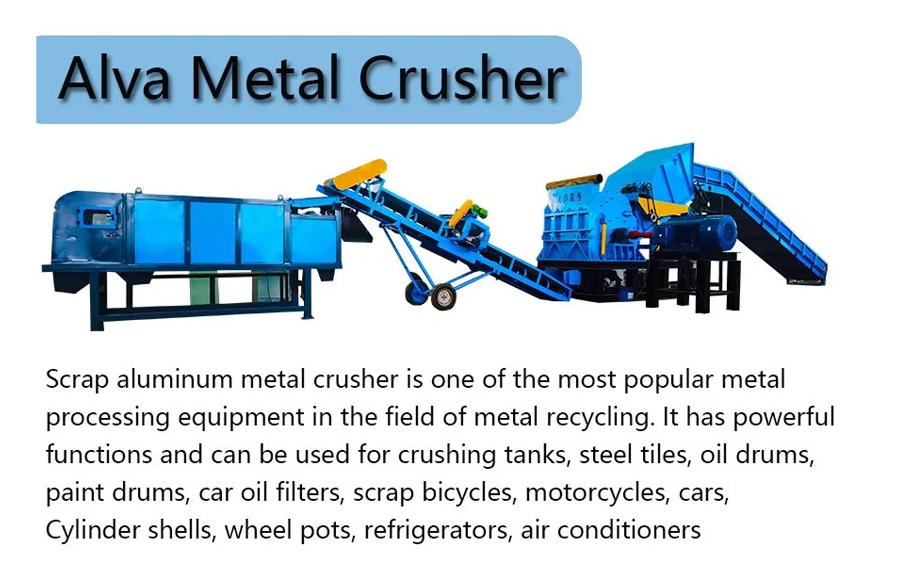

The scrap steel shredder is designed to shred a wide variety of light and thin material as discarded automobiles, tin plate, household appliances, bicycles ,empty cans, etc. It can make the materials into pure charge for steel making. Through smashing and compressing, the shredder can remove the impurities, raise densities. Lower transporting and smelting cost offer customers a good furnace charge of steel plant.

Product Parameters

| S/N | Model | Feed size(mm) | Fain motorpower(kw) | Monolith

output(t/h) |

Processing material

output(t/h) |

Distribution

Transformer Requirements(kv) |

L(m) | W(m) | H(m) | Floorarea(m²) |

| 1 | ALVA-MCM-75 | 900mm | 75KW | 1 | 2 | 125KVA | 21 | 4 | 2.7 | 100m² |

| 2 | ALVA-MCM-110 | 1000mm | 110KW | 1.5 | 2.5 | 160KVA | 34 | 4 | 2.78 | 1150m² |

| 3 | ALVA-MCM-132 | 1260mm | 132KW | 1 | 3 | 200KVA | 36 | 4.5 | 2.8 | 180m² |

| 4 | ALVA-MCM-160 | 1460mm | 160KW | 3~4 | 5~6 | 250KVA | 36 | 5 | 2.9 | 280m² |

| 5 | ALVA-MCM-200 | 1500mm | 200KW | 4~5 | 7~8 | 315KVA | 37 | 6 | 3.3 | 300m² |

| 6 | ALVA-MCM-315 | 1600mm | 315KW | 6~7 | 8~10 | 500KVA | 39 | 6.5 | 4.5 | 350m² |

| 7 | ALVA-MCM-450 | 1600mm | 450KW | 8~9 | 10~12 | 630KVA | 48 | 7 | 6.0 | 480m² |

| 8 | ALVA-MCM-630 | 1800mm | 630KW | 10~11 | 14~16 | 10KVA | 55 | 7.5 | 6.0 | 1000m² |

| 9 | ALVA-MCM-750 | 1800mm | 750KW | 11~12 | 16~18 | 10KVA | 60 | 7.5 | 6.0 | 1000m² |

| 10 | ALVA-MCM-900 | 220mm | 9900KW | 14~15 | 18~20 | 10KVA | 75 | 8 | 7.2 | 1160m² |

| 11 | ALVA-MCM-2000 | 250mm | 1600KW | 16~18 | 22~24 | 10KVA | 80 | 9 | 7.6 | 1700m² |

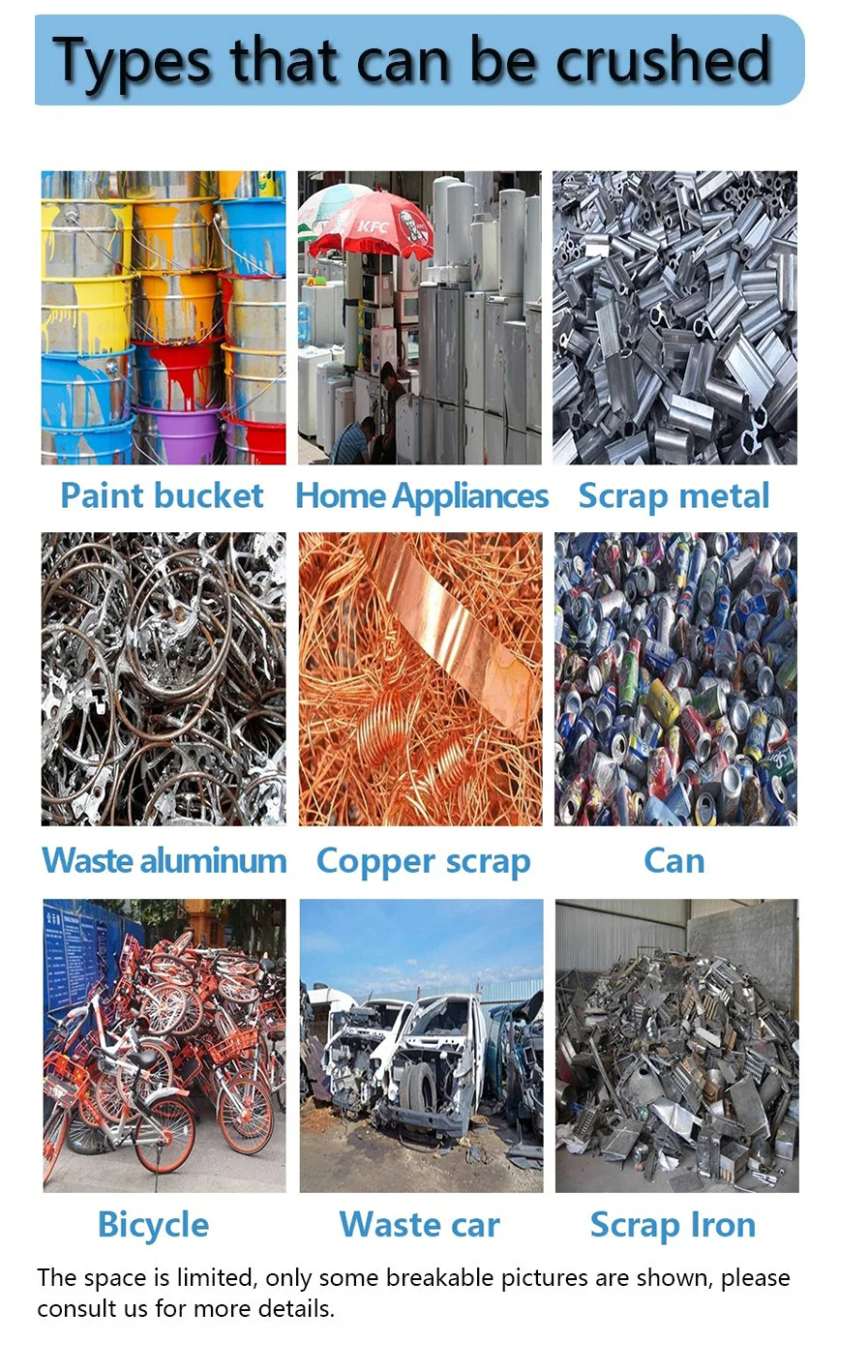

2.Products that can be crushed

This machine can be used to crush:

1) The whole or flattened car bodies(excluding tires,gasoline,cylinders, tanks, engines and gear boxes)

2) Tinplate categories

3) Home electrical appliances(excluding motors,compressors and axles)

4) Bicycle bodies and similar materials

5) Empty tanks(excluding liquids,oil pant,etc)

6) Other materials which are suitable for shredder.

3.Product superiority

1).Dense reinforcement plate, strong and durable

2).Wear resistant and durable, can extend the service life

3).Use wear-resistant and thickened material

4).Feed more power, with a forced feeder

5).Excellent performance, easy to use and reprocessing

4.product picture

5.Main features

1) Using microcomputer control system, the operation is easy and simple

2) Driven by servo motor and precision screw feed.

3) It is equipped with touch screen , very convenient to change thickness and other parameters .

Why Choose Us:

FAQ:

Q1: Can you customize products for clients?

A1: Yes, we can customize and produce crushing machinery according to customers’ requirements or drawings.

Q2: What about your products quality?

A2: We can provide you samples for quality inspection. If you order, we guarantee the quality is same with sample. In case of quality problem, we can sign agreements and our company will perform the duties.

Q3: How can we trust your factory?

A3: We recommend that you come to our factory to see the goods,to verify the real situation of the products, and know more about our factory.

Q4: Why does the price often change?

A4: The price depends on the latest prices of the raw materials.

Q5: What about the contract signing?

A5: If you’re satisfied with the products and our service, you can sign the contract with us, pay the deposit Then we’ll produce the machines as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of the products and the accessories are complete.

Q6: How about delivery?

A: when the product is ready, it can be delivered to you after your full payment. Will provide technical guidance.