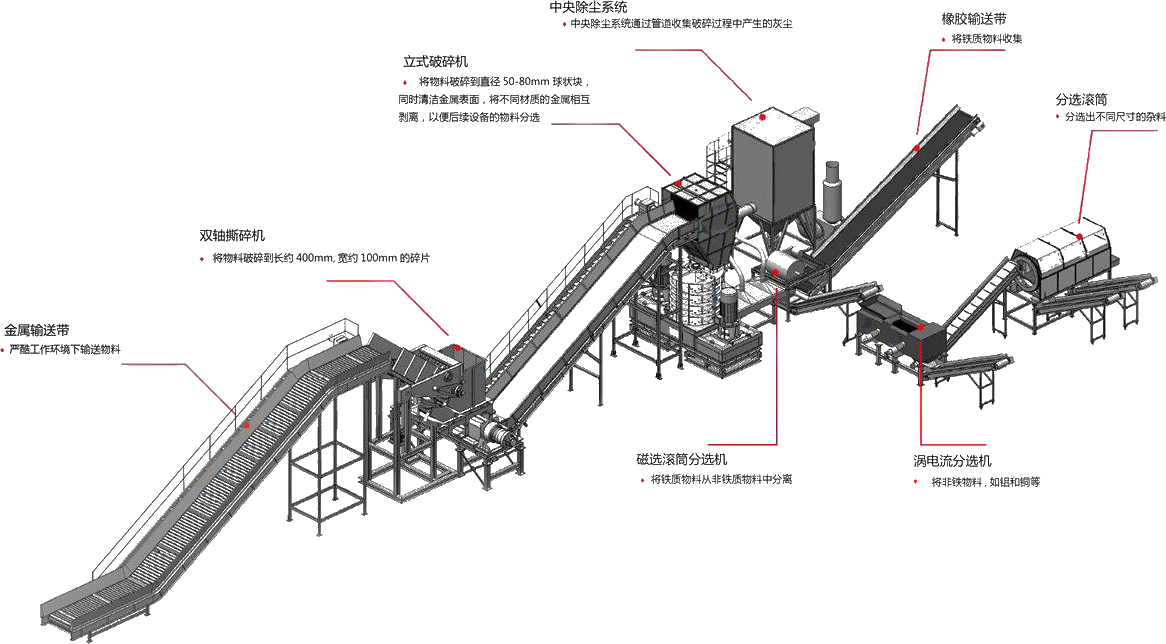

Production Process

Configuration of scrap steel crusher production line

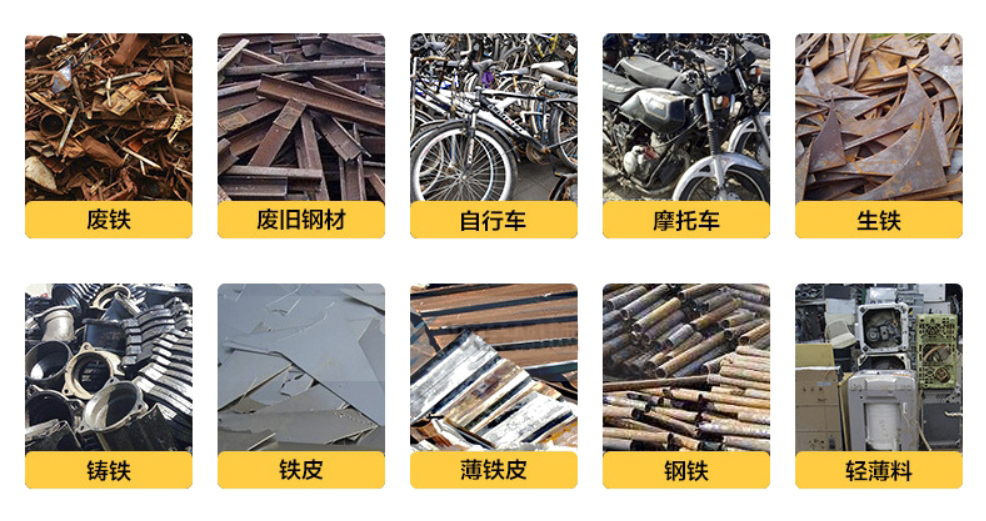

The metal shredder production line, also known as the scrap steel crushing production line, belongs to the scrap metal recycling production line equipment, used for crushing and processing large volume scrap steel materials and various metal materials. The shredder production line is specially designed by Shuangxing Machinery for processing various household waste products such as color steel tiles, waste bicycles, automobiles, waste aluminum and raw aluminum, as well as crushing various types of scrap steel with a thickness of less than 8 millimeters.

Based on the crushing raw materials, Shuangxing Machinery selects reasonable production line equipment for users, which is in line with actual production needs, reduces customer capital investment, and allows users to obtain cost-effective scrap steel crushing production lines and shredder production lines while controlling costs.

Production process: feeding conveyor (chain plate conveyor optional) → double axis shredder → scrap steel crusher → discharge conveyor → magnetic separator → eddy current separator → discharge conveyor → dust collector

Materials used in the production line:

Production line supports customization

The shredder production line is an efficient choice for crushing and sorting, and it is also an inevitable trend for automation and environmental protection. The complete set of environmental protection treatment equipment developed and produced by shredder manufacturer Haoxing Machinery is mainly aimed at shredding, crushing, and separating scrap iron, scrap steel, scrap aluminum alloy, broken bridge aluminum, aluminum profiles, and engine casings, etc. It is convenient for recycling and supports customer customization.

1. Production line automation

The environmental pressure and the continuous expansion of the waste crushing and recycling market have raised the working capacity requirements of metal crushers and other processing equipment. To achieve the efficiency of the shredder production line, it is necessary to rely on automated crushing methods and control methods, as well as advanced automated manufacturing modules and automated production equipment.

The shredder production line can be controlled by a digital computer system to automatically control the speed, production situation, and material particle size information control system of the material storage and transportation production line. It is a system technology that realizes automated work by setting programs according to production needs. At the same time, combined with the auxiliary design and monitoring technology of programmable control systems, it will develop the enterprise towards fully automated work direction.

2. Customization of production lines

At present, customized and modular production line technology has been widely promoted and used, which fully integrates the crushing machine process with the production line process. Users can choose equipment based on materials and production scale, reduce equipment procurement costs, and achieve the best production effect.

3. Environmental trends in production lines

The overall configuration of the shredder production line is also developing towards low noise pollution, low dust pollution, and low power consumption, which is the best treatment mode for waste recycling. According to national environmental and energy policies and regulations, Haoxing Machinery conducts detailed data on energy and resource consumption in the product manufacturing process, analyzes equipment problems, and formulates green production process plans that meet standards to achieve energy conservation, emission reduction, and efficient resource utilization.