At present, the total amount of scrap steel produced in the world every year is 3.5-4.5 billion tons, accounting for about 45-50% of the total steel production, of which 85-90% is used as raw material for steelmaking, and 10-15% is used for casting, ironmaking and recycled steel. . Therefore, the utilization of scrap steel has attracted widespread attention from society and is called the “second mining industry”. Many countries lack iron ore or the grade of iron ore is declining, and they pay more attention to scrap steel. The supply and marketing of scrap steel has become an important international market. Since the 1970s, the output of electric furnace steel using scrap steel as raw materials has developed significantly in the world, which also shows that the scope of utilization of scrap steel is expanding. Due to the extensive use of scrap steel, the current world pig iron production is only 72% of steel production.

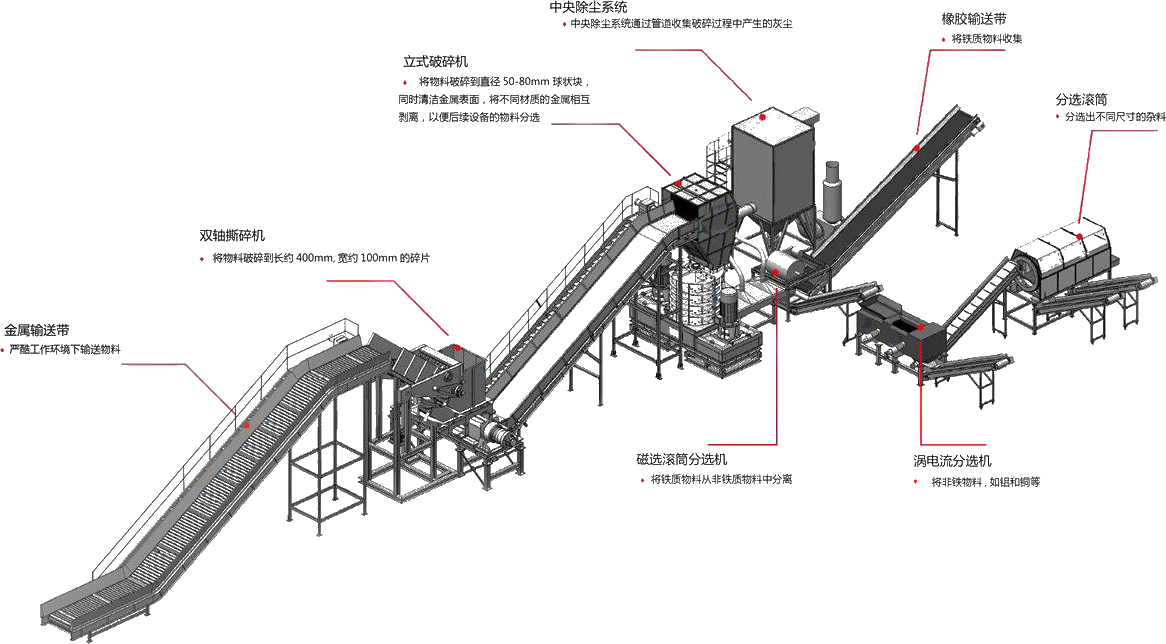

Scrap steel and scrap iron crushing and recycling process, scrap steel processing methods adopt different crushing treatment plans due to material, shape, and fragility.

1. Large scrap steel with extra thickness and length is cut into qualified size by blasting method and flame cutter.

2. Use a shearing machine to cut thick scrap steel plates, shaped steel, and steel bars.

3. Use metal crushers to crush light materials with small volume proportions such as scrap sheet scraps, scrap steel wires, and scrap car casings.

After the scrap iron materials are crushed into granules, the materials are then magnetically separated. Magnetic separation uses the magnetism of metal iron to magnetically sort various impurities contained in the crushed scrap iron materials to achieve several levels of metal iron. sorting and separation effect.